Notice: Undefined offset: 1 in /home/digit572/adidasblog.com/wp-content/themes/jnews/class/ContentTag.php on line 86

Notice: Undefined offset: 1 in /home/digit572/adidasblog.com/wp-content/themes/jnews/class/ContentTag.php on line 86

[ad_1]

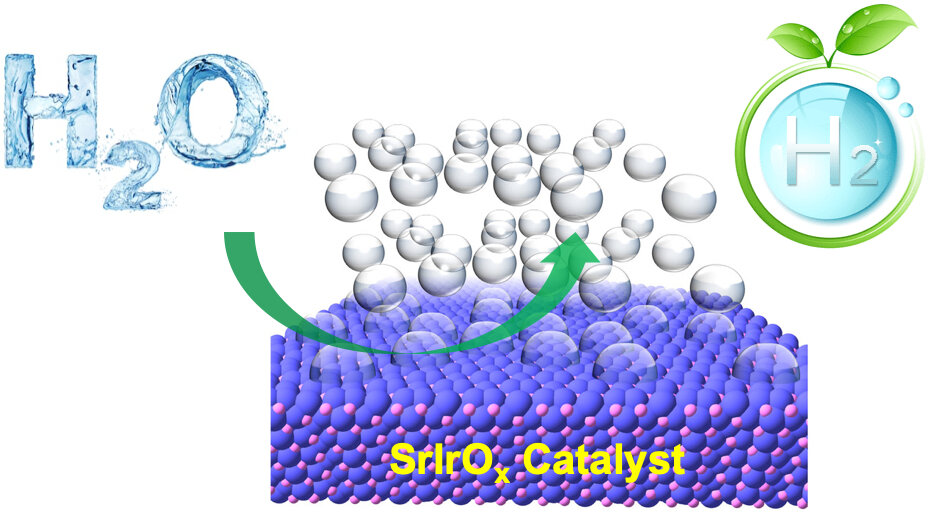

Effectively mass-producing hydrogen from water is nearer to changing into a actuality because of Oregon State College School of Engineering researchers and collaborators at Cornell College and the Argonne Nationwide Laboratory.

The scientists used superior experimental instruments to forge a clearer understanding of an electrochemical catalytic process that is cleaner and extra sustainable than deriving hydrogen from pure gasoline.

Findings have been revealed as we speak in Science Advances.

Hydrogen is present in a variety of compounds on Earth, mostly combining with oxygen to make water, and it has many scientific, industrial and energy-related roles. It additionally happens within the type of hydrocarbons, compounds consisting of hydrogen and carbon comparable to methane, the first part of pure gasoline.

“The manufacturing of hydrogen is essential for a lot of features of our life, comparable to gasoline cells for automobiles and the manufacture of many helpful chemical compounds comparable to ammonia,” stated Oregon State’s Zhenxing Feng, a chemical engineering professor who led the examine. “It is also used within the refining of metals, for producing man-made supplies comparable to plastics and for a variety of different functions.”

In accordance with the Division of Power, the US produces most of its hydrogen from a methane supply comparable to pure gasoline through a way often called steam-methane reforming. The method includes subjecting methane to pressurized steam within the presence of a catalyst, making a response that produces hydrogen and carbon monoxide, in addition to a small quantity of carbon dioxide.

The following step is known as the water-gas shift reaction during which the carbon monoxide and steam are reacted through a unique catalyst, making carbon dioxide and extra hydrogen. Within the final step, pressure-swing adsorption, carbon dioxide and different impurities are eliminated, forsaking pure hydrogen.

“In comparison with natural gas reforming, using electrical energy from renewable sources to separate water for hydrogen is cleaner and extra sustainable,” Feng stated. “Nonetheless, the effectivity of water-splitting is low, primarily because of the excessive overpotential—the distinction between the precise potential and the theoretical potential of an electrochemical response—of 1 key half-reaction within the course of, the oxygen evolution reaction or OER.”

A half-reaction is both of the 2 elements of a redox, or reduction-oxidation, response during which electrons are transferred between two reactants; discount refers to gaining electrons, oxidation means dropping electrons.

The idea of half-reactions is usually used to explain what goes on in an electrochemical cell, and half-reactions are generally used as a approach to steadiness redox reactions. Overpotential is the margin between the theoretical voltage and the precise voltage essential to trigger electrolysis—a chemical response pushed by the applying of electrical present.

“Electrocatalysts are vital to selling the water-splitting response by decreasing the overpotential, however growing high-performance electrocatalysts is much from easy,” Feng stated. “One of many main hurdles is the ignorance concerning the evolving construction of the electrocatalysts through the electrochemical operations. Understanding the structural and chemical evolution of the electrocatalyst through the OER is crucial to growing high-quality electrocatalyst supplies and, in flip, vitality sustainability.”

Feng and collaborators used a set of superior characterization instruments to check the atomic structural evolution of a state-of-the artwork OER electrocatalyst, strontium iridate (SrIrO3), in acid electrolyte.

“We wished to grasp the origin of its record-high exercise for the OER—1,000 instances greater than the widespread industrial catalyst, iridium oxide,” Feng stated. “Utilizing synchrotron-based X-ray amenities at Argonne and lab-based X-ray photoelectron spectroscopy on the Northwest Nanotechnology Infrastructure website at OSU, we noticed the floor chemical and crystalline-to-amorphous transformation of SrIrO3 through the OER.”

The observations led to a deep understanding of what was occurring behind strontium iridate’s potential to work so effectively as a catalyst.

“Our detailed, atomic-scale discovering explains how the energetic strontium iridate layer kinds on strontium iridate and factors to the vital function of the lattice oxygen activation and paired ionic diffusion on the formation of the energetic OER items,” he stated.

Feng added that the work supplies perception into how utilized potential facilitates the formation of the purposeful amorphous layers on the electrochemical interface and results in potentialities for the design of higher catalysts.

Gang Wan et al. Amorphization mechanism of SrIrO3 electrocatalyst: How oxygen redox initiates ionic diffusion and structural reorganization, Science Advances (2021). DOI: 10.1126/sciadv.abc7323

Quotation:

Researchers take key step towards cleaner, extra sustainable manufacturing of hydrogen (2021, January 9)

retrieved 9 January 2021

from https://phys.org/information/2021-01-key-cleaner-sustainable-production-hydrogen.html

This doc is topic to copyright. Aside from any honest dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for data functions solely.

[ad_2]

Source link