[ad_1]

UK-based fluid energy techniques producer Domin has deployed steel 3D printing know-how from international engineering agency Renishaw to supply a spread of high-performance servo valves that would assist to slash carbon dioxide (CO2) emissions from the fluid energy business.

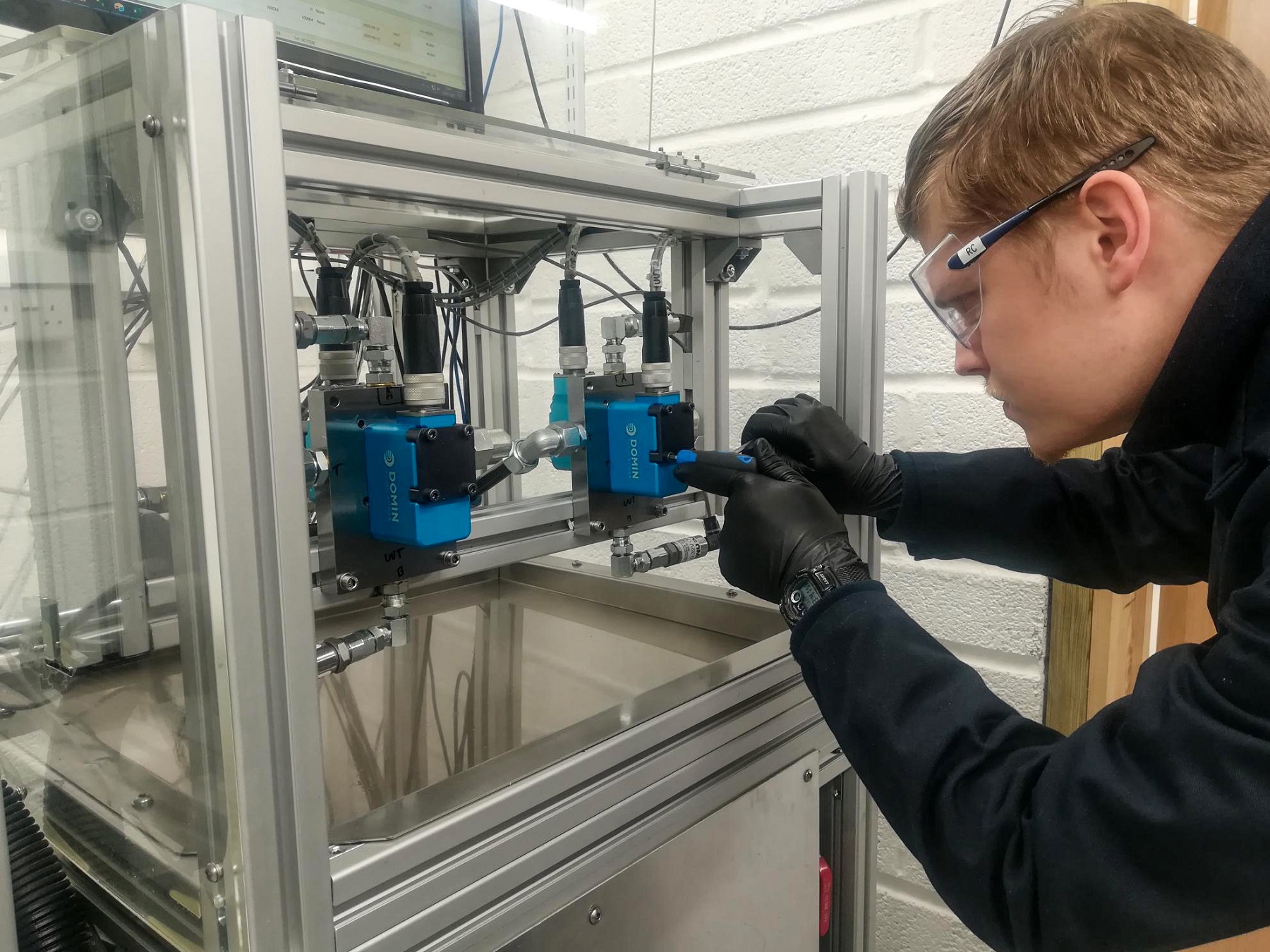

Usually used to regulate highly effective hydraulic cylinders, a servo valve is an electrically-operated valve that controls hydraulic fluid by turning alerts into stress. Produced utilizing Renishaw’s RenAM 500Q additive manufacturing system, every of Domin’s 3D printed servo valves can save as much as one tonne of CO2 in comparison with their conventionally manufactured counterparts.

“There’s a urgent purpose disruption is required – sustainability,” mentioned Marcus Pont, CEO of Domin. “Within the US, the fluid energy sector alone wastes about 300 million tonnes of CO2 per 12 months by system inefficiencies. To place this into context, that is about the identical as the whole output for all CO2 emissions within the UK.

“Extra environment friendly know-how may make an actual distinction to international emissions.”

Domin’s adoption of steel 3D printing

Fluid energy techniques make the most of liquids or gases underneath stress to generate and transmit power, and are generally utilized in markets spanning Components 1, automotive, house, aerospace, cellular hydraulics, and industrial crops.

In line with Domin, whereas a number of applied sciences have been launched to the business in latest many years there may be but to be one which causes “vital sufficient” change within the fluid energy market by way of enhancing sustainability.

Nevertheless, the corporate sees 3D printing because the “lacking piece of the puzzle” to alter this, and in 2019 embarked upon its partnership with Renishaw to redevelop quite a few its merchandise.

Domin used the RenAM 500Q system to start redesigning its direct drive servo valves, making them 25 p.c extra highly effective than the unique whereas being 1 / 4 of the dimensions. The redesigned valves had been produced for a 3rd of the fee and the manufacturing time was additionally considerably decreased.

Domin has additionally lately utilized additive manufacturing to a different mission with main luxurious sports activities automotive producer Aston Martin and Cranfield University, which goals to develop a “world-leading” suspension system involving 3D printing. The design of the suspension system shall be primarily based on Domin’s patented valve know-how, involving a 3D printed core that accommodates 25 fluid galleries working in unison to move hydraulic fluid all through the system.

Lowering emissions within the fluid energy sector

Now that Domin has developed its vary of 3D printed state-of-the-art servo valves, the corporate hopes to showcase how engineering startups can drive worth for the UK’s business.

“Britain is house to a number of the world’s main engineering companies,” mentioned Pont. “Nevertheless, many of the UK’s huge engineering companies had been began within the twentieth Century. It’s time for British enterprise to grow to be extra bold. Combining steel additive manufacturing with different applied sciences revolutionizes what will be achieved technically – it may generate actual worth for British business.”

RenAM 500Q is a quad laser steel additive manufacturing machine launched by Renishaw in 2017. The machine has a excessive most deposition fee of 150 cm³ per hour to enhance productiveness and decrease value per half, and likewise options automated powder and waste dealing with techniques to make sure constant course of high quality.

By utilizing the RenAM 500Q to re-engineer and manufacture the servo valves, Domin was capable of enhance productiveness and cut back value per half, whereas realizing larger design freedom. Designed for probably the most demanding servo purposes, the 3D printed valves are marketed by Domin as small, mild, and reasonably priced high-performance merchandise that supply good energy density and dynamic efficiency.

With every 3D printed valve capable of save as much as a tonne of CO2 emissions in comparison with conventionally manufactured valves, Pont sees the vary as simply “step one” in creating change throughout the UK’s fluid energy techniques sector. Going forwards, the corporate will look to begin manufacturing and promoting full techniques, whereas engaged on quite a few high-profile initiatives.

“Additive manufacturing is proving to be a key enabler in lots of markets,” mentioned Bryan Austin, Director of Gross sales, Additive Manufacturing Group at Renishaw. The productiveness that Renishaw’s know-how permits means steel 3D printing is broadening into markets the place it was beforehand economical.

“Domin has showcased how AM can be utilized to make merchandise higher, sooner, and cheaper than conventional manufacturing would permit.”

Subscribe to the 3D Printing Industry newsletter for the most recent information in additive manufacturing. You may as well keep linked by following us on Twitter and liking us on Facebook.

Searching for a profession in additive manufacturing? Go to 3D Printing Jobs for a number of roles within the business.

Featured picture reveals Renishaw’s AM know-how has enabled Domin to revamp and enhance its servo valves. Photograph through Renishaw.

[ad_2]

Source link