[ad_1]

South Korean 3D printer producer Sindoh has launched its industrial polymer 3D printer, the Sindoh S100, which has grow to be the primary business machine to supply Materialise’s Bluesint PA12 course of expertise and allow 3D printing with as much as one hundred pc recycled powder.

Along with Bluesint PA12, every S100 comes bundled with Materialise’s Magics 25 3D printing software program, its Build Processor and accompanying management platform (MCP), and is absolutely appropriate with Magics RP and the corporate’s Streamics operations administration software program.

In flip, Materialise has acquired 5 S100 printers, turning into the primary firm to acquire Sindoh’s newest machine.

“Bluesint PA12 represents a significant step in direction of making 3D printing extra sustainable,” mentioned Fried Vancraen, CEO of Materialise. “The introduction of the Sindoh S100 printer, the primary to help Bluesint PA12, will assist us empower our clients to choose for sustainability.”

Decreasing powder waste with Bluesint PA12

Materialise unveiled its Bluesint PA12 technology in November final 12 months, designed to drastically enhance the useful resource effectivity of the laser sintering 3D printing course of by enabling printing with as much as one hundred pc reused powder.

The expertise seeks to beat the “orange-peel” impact usually noticed in components printed with reused powder, attributable to the cooling of layers. This will go away components with an uneven floor and diminished energy.

Elements printed with reused powder utilizing Materialise’s Bluesint PA12 expertise, nevertheless, reportedly have related mechanical and visible properties to different recent powders utilized in laser sintering. That is achieved by way of two lasers, one to sinter a brand new layer, whereas the opposite maintains the earlier layer on the appropriate temperature.

As such, along with considerably lowering powder waste throughout 3D printing, Blueprint PA12 additionally delivers components with fascinating technical specs, too.

By integrating Materialise’s Bluesint PA12 expertise, the Sindoh S100 is believed to be the primary commercially obtainable machine that may print with as much as one hundred pc recycled powder.

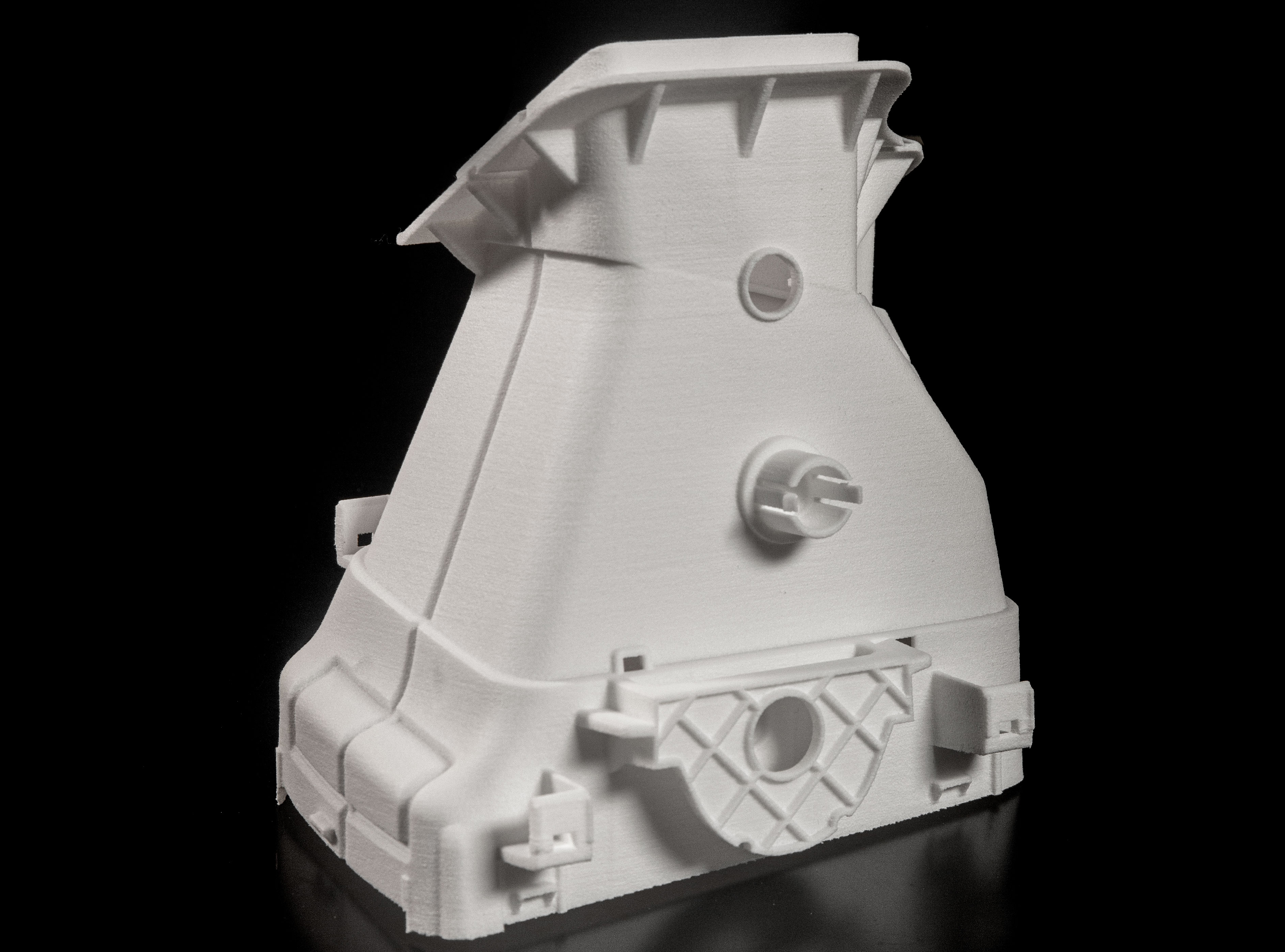

The Sindoh S100

The Sindoh S100 is the primary industrial polymer 3D printer from the South Korean producer, identified for its fused filament fabrication (FFF) desktop vary, together with its 3D WOX1, 3DWOX 2X and DP200 machines. Up to now, Sindoh additionally collaborated with Japanese digital printing specialist Mimaki on a co-branded FFF printer, the 3DFF-222, designed for the in-house manufacturing of customized jigs and fixtures.

Sindoh’s latest machine provides a big construct quantity of 510 x 510 x 500 mm, and is supplied with a dual-feed system to extend print productiveness. The printer provides a scanning velocity of as much as 15 meters per second and options two lasers with versatile spot sizes because of its 3D axes scanning expertise, enabling on-the-fly modifications to every laser’s spot measurement unbiased of one another.

The S100 can be able to working with layers of variable thickness, whereas its semi-automatic calibration operate and distant diagnostic upkeep capabilities assist to make sure excessive operational effectivity.

In a position to facilitate processing temperatures as much as 200℃, the machine is appropriate with all kinds of polymer supplies, together with Evonik PA12, BASF Ultrasint PA11, TPU, and PP.

Engineers are in a position to optimize and personalize the 3D printing course of by tweaking the machine and course of parameters by Materialise’s Magics 25, Construct Processor, and MCP software program bundle, which allows wonderful temperature management and edge printing high quality. Moreover, the Magics RP and Streamics add-ons allow the machine to help industry-scale 3D printing manufacturing. The Sindoh S100 3D printer is now obtainable to order with supply schedules for Q2 2021.

“Sindoh S100 has each efficiency and financial values by its giant construct quantity and an unparalleled recycling price,” mentioned Dr. Woo Suk-Hyung, Chairman of Sindoh. “This new product additionally demonstrates the wonderful synergy of Materialise software program and the 60 years of {hardware} manufacturing expertise of Sindoh.

“Combining the newest applied sciences of each firms, it allows vital discount in manufacturing price in addition to wonderful printing efficiency.”

Subscribe to the 3D Printing Industry newsletter for the newest information in additive manufacturing. You may also keep related by following us on Twitter and liking us on Facebook.

In search of a profession in additive manufacturing? Go to 3D Printing Jobs for a number of roles within the {industry}.

Featured picture reveals the Sindoh S100 polymer 3D printer. Picture by way of Sindoh.

[ad_2]

Source link

![WordPress database error: [You have an error in your SQL syntax; check the manual that corresponds to your MariaDB server version for the right syntax to use near ‘+thisValue3+ where ID_P=’+thisValue2+” at line 1]SELECT * FROM players_+thisValue3+ where ID_P=’+thisValue2+’Stats Players | Tennis Tonic](https://adidasblog.digitalsnazz.com/wp-content/uploads/2020/12/1609113710_Facebook-default-75x75.jpg)