[ad_1]

NOVUM, an EU-funded mission that’s a part of the Horizon 2020 program, is producing parts from cellulose-based supplies by 3D printing to be used inside a number of various industries.

The mission goals to handle the rising international consciousness round useful resource sufficiency, local weather change mitigation, and the round economic system, by exploring cellulose as an alternative to fossil-based supplies for functions throughout the automotive, marine, and electrical insulation sectors.

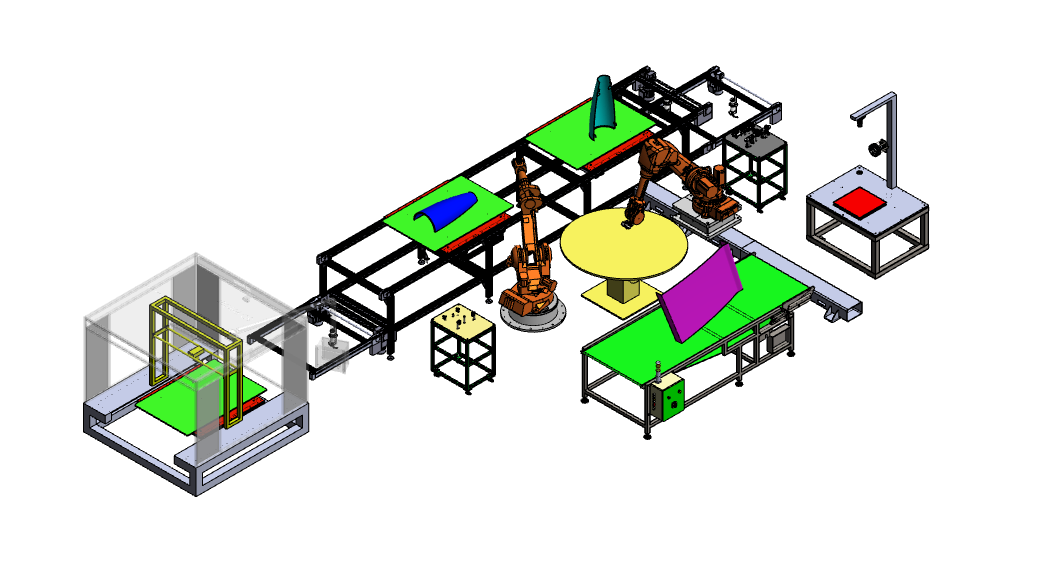

Comprised of 10 totally different companions spanning varied ranges of the worth chain, the mission includes the event of cellulose-based supplies optimized for 3D printing and the development of a pilot line to show the printed parts.

Printing cellulose-based supplies

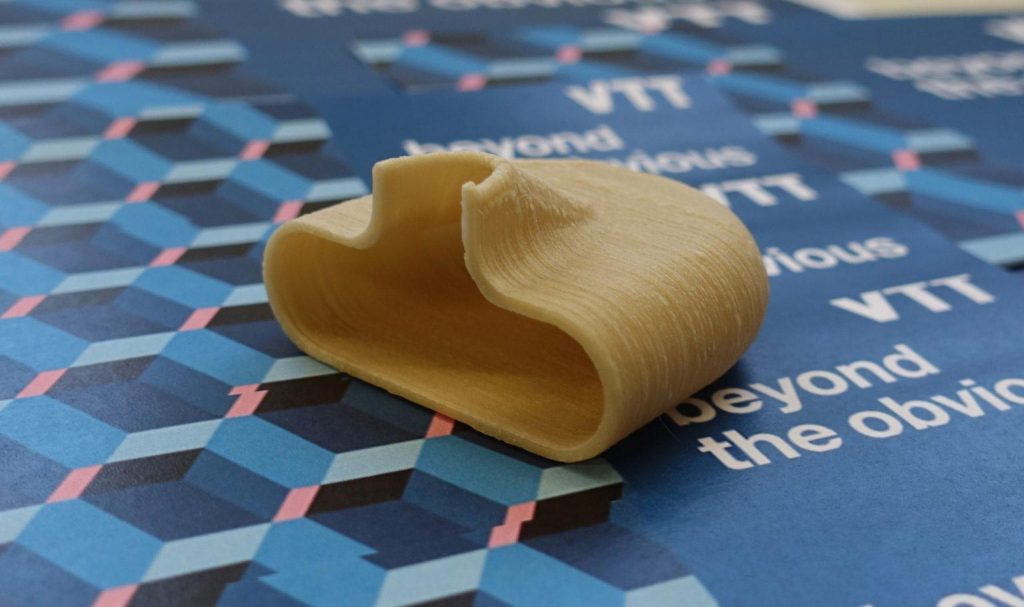

The thermoplastic supplies developed through the mission comprise cellulose derivatives, cellulose powders, and bio-based plasticizers, and have a 60 p.c larger cellulose content material than “business references”. Regardless of this, they exhibit the identical and even higher materials power properties and might be tuned in response to the necessities of end-use functions.

Cellulose was chosen as a foundation for the supplies developed within the mission resulting from its potential as a pure, sustainable, and versatile alternative for a lot of artificial supplies. When contemplating the mix of cellulose and 3D printing, cellulose is just not thermoplastic by nature, which is the important thing problem the mission contributors are searching for to handle.

The developed cellulose-based supplies might be printed utilizing generally obtainable 3D printing applied sciences reminiscent of Fused Filament Fabrication (FFF), and the tip merchandise are light-weight and have a easy floor. In the course of the mission lifeline, the fabric growth and printing processes can be demonstrated by the creation of parts to be used throughout the electrical insulation, marine, and automotive industries.

A number of sector functions

Cellulose is already a typical uncooked materials throughout the manufacturing {of electrical} insulation parts, nonetheless present manufacturing strategies are inefficient when it comes to labor, time, power, and waste technology, in response to the mission contributors. By growing a technique of 3D printing cellulose-based supplies to create parts appropriate for this discipline, the contributors hope to spice up the effectivity of the manufacturing course of whereas eradicating the necessity for molds.

Elsewhere, out of doors ornamental components for cruise ships are a doable use case for the developed know-how throughout the marine sector, whereas within the automotive sector the bio-based supplies may substitute fossil-based supplies and contribute to bettering sustainability throughout the trade.

The mission can be exploring the 3D printing of wooden fiber foams to create thick and porous fibrous buildings that don’t collapse upon drying. Whereas know-how for producing such buildings in 2D has already been established, creating them in 3D through additive manufacturing is reportedly new territory. The mission contributors are investigating the optimum fiber-foam combine for the 3D printing course of, layer binding concerns, and the way drying occasions might be minimized.

The mission has already carried out profitable trials to print the wooden fiber foam buildings utilizing an extruder-type nozzle, and the following step is to discover how a business 3D printer might be tailored for the method. In line with the contributors, potential functions for most of these buildings lie throughout the building and transportation sectors as insulation supplies for sound and vibration.

3D printing with cellulose

Cellulose has been utilized throughout the creation of extra sustainable 3D printing feedstock for a number of years. In 2017, cellulose nanocrystal (CNC) inks for 3D printing have been developed as a part of a mission carried out by Empa, a bunch on the Swiss Federal Laboratories for Supplies Science and Know-how, which sought to render supplies appropriate for biomedical functions. The group has since studied the results of sheer stress utilized to the ink when extruded utilizing direct ink writing, and has experimented with tuning the orientation of CNC “building blocks” to attain totally different properties in finish merchandise.

Researchers from the University of Bristol and the University of Bath have beforehand explored the potential for the 4D printing of cellulose, utilizing a 3D printed ink that harnesses cellulose fibers to rework in response to water, and nanocellulose has additionally been recognized as having the potential to transform the 3D printed food sector.

Elsewhere, Oak Ridge National Laboratory (ORNL) and the University of Maine have been granted $20 million in US federal funding to create bio-based 3D printable materials for large-scale additive manufacturing, together with using cellulose nanofiber.

Subscribe to the 3D Printing Industry newsletter for the most recent information in additive manufacturing. You may also keep related by following us on Twitter and liking us on Facebook.

Searching for a profession in additive manufacturing? Go to 3D Printing Jobs for a number of roles within the trade.

Featured picture exhibits lamp shade 3D printed from the cellulose-based supplies by FDM. Picture through NOVUM.

[ad_2]

Source link

![WordPress database error: [You have an error in your SQL syntax; check the manual that corresponds to your MariaDB server version for the right syntax to use near ‘+thisValue3+ where ID_P=’+thisValue2+” at line 1]SELECT * FROM players_+thisValue3+ where ID_P=’+thisValue2+’Stats Players | Tennis Tonic](https://adidasblog.digitalsnazz.com/wp-content/uploads/2020/12/1609113710_Facebook-default-75x75.jpg)